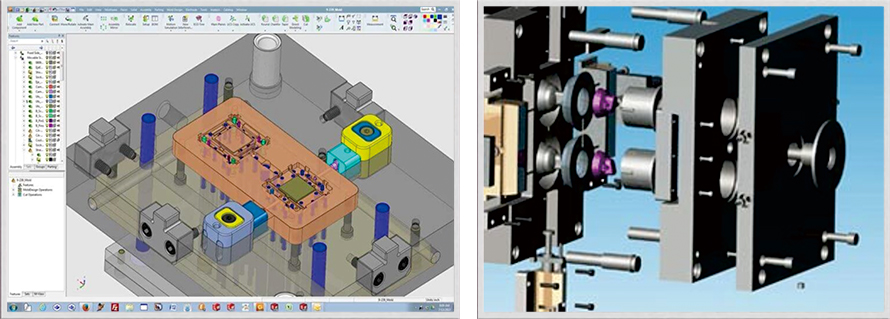

Mold Design

CTM has a knowledgeable and experienced team of engineers to help you with the engineering side of your project. With over 18 years of combined experience in plastics engineering, design, development, the manufacture of custom injection mould and plastic injection, we can assist with material selection, part design and make tooling recommendations.

Our understanding of the correct mould design needed to support your material selection and tolerance requirements allows us to build the right tool for the job. We routinely work with our customers to develop working components that maximize the potential of their selected resins and minimize part cost.

We offer unique solutions to your product problems. Working with information age technologies and advanced mould-making processes, CTM can quickly respond to your tooling needs and produce precision custom injection mould in the shortest time. We work with you to analyze your projects to identify cost-savings opportunities as we integrate quality and confirm manufacturability CTM can work with a variety of CAD formats: SolidWorks, ProE and CADKEY internally. We also work the “old fashion way”, with your drawings, sketches, models, parts or existing molds. Another thing the old fashion way, our quality and service.

Modern toolmakers must use 3D models to make the mold cavities. CTM has extensive experience using UG to design and build molds. While formats are constantly changing, we have successfully imported from programs, including Pro/ENGINEER, CATIA, Solid Edge, and AutoCAD. In addition, we use universal formats such as IGES, STEP, DXF, DWG, parasolid (x_t) ect.